TaC coating strengthens automotive components by providing unmatched wear resistance. Its extreme hardness reduces friction and prevents abrasion. You benefit from its thermal stability, which protects parts in high-temperature environments. The TAC coatings market continues to grow as industries adopt this advanced solution. TAC coating technology ensures durability and peak performance under stress.

Key Takeaways

- TaC coating is very hard, so parts last longer.

- It stays strong in high heat, protecting turbochargers and exhausts.

- TaC coating saves money by lowering repair and replacement needs.

Unique Properties of TaC Coating

Exceptional Hardness and Durability

TaC coating stands out for its exceptional hardness, which makes it one of the most durable materials available for automotive applications. You can rely on its ability to resist scratches, dents, and other forms of mechanical wear. This hardness ensures that components maintain their structural integrity even under heavy loads or prolonged use. For example, when applied to engine parts, TaC coating minimizes surface damage caused by friction. This durability translates into longer-lasting components, reducing the need for frequent replacements.

Thermal Stability and Chemical Resistance

High-performance automotive components often operate in extreme temperatures. TaC coating excels in these conditions due to its remarkable thermal stability. It resists degradation even at temperatures exceeding 3,000°F, making it ideal for parts like turbochargers and exhaust systems. Additionally, its chemical resistance protects components from corrosive substances such as fuel additives and exhaust gases. This dual protection ensures that your vehicle’s critical parts perform reliably in harsh environments.

Adhesion and Performance in Extreme Conditions

TaC coating adheres strongly to various substrates, ensuring it stays intact during operation. This strong adhesion prevents peeling or flaking, even when exposed to rapid temperature changes or mechanical stress. You’ll notice improved performance in extreme conditions, as the coating reduces friction and wear. Whether in high-speed engines or off-road vehicles, TaC coating enhances reliability and efficiency.

How TaC Coating Enhances Wear Resistance

Mechanisms of Wear Resistance

TaC Coating protects automotive components by creating a barrier against wear. Its dense structure resists surface damage caused by friction and abrasion. You’ll notice how it prevents material loss, even under heavy mechanical stress. The coating’s ability to distribute force evenly reduces localized damage, ensuring parts last longer.

Tipp: TaC Coating works best when applied to components exposed to constant movement or pressure, such as bearings and pistons.

Role of Hardness and Friction Reduction

The hardness of TaC Coating plays a key role in reducing wear. Its tough surface minimizes deformation, keeping parts intact during operation. You’ll find that this hardness also lowers friction between moving parts. Reduced friction means less heat generation, which protects components from overheating. This combination of hardness and friction reduction ensures smoother performance and longer service life.

Performance in High-Temperature Environments

High-performance vehicles often operate in extreme heat. TaC Coating excels in these conditions by maintaining its properties at elevated temperatures. You’ll see its effectiveness in turbochargers and exhaust systems, where temperatures can exceed 3,000°F. The coating prevents thermal degradation, ensuring reliable performance. Its ability to withstand heat also reduces the risk of component failure, making it ideal for demanding applications.

Applications of TaC Coating in Automotive Components

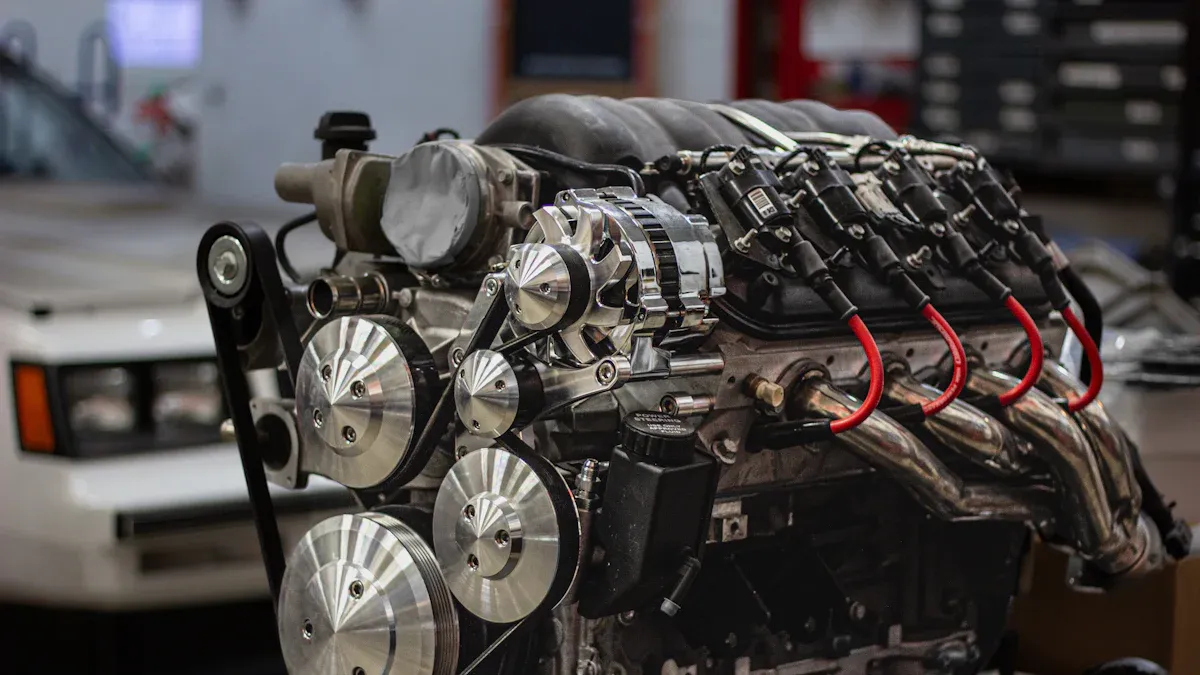

Engine Components

You rely on engine components to handle intense pressure and friction during operation. TaC Coating strengthens these parts by reducing wear and extending their lifespan. Pistons, valves, and cylinder liners benefit the most from this advanced coating. It creates a hard, protective layer that resists abrasion and minimizes surface damage. This ensures smoother engine performance and reduces the risk of breakdowns. By using TaC Coating, you can improve the durability of your engine and lower maintenance costs.

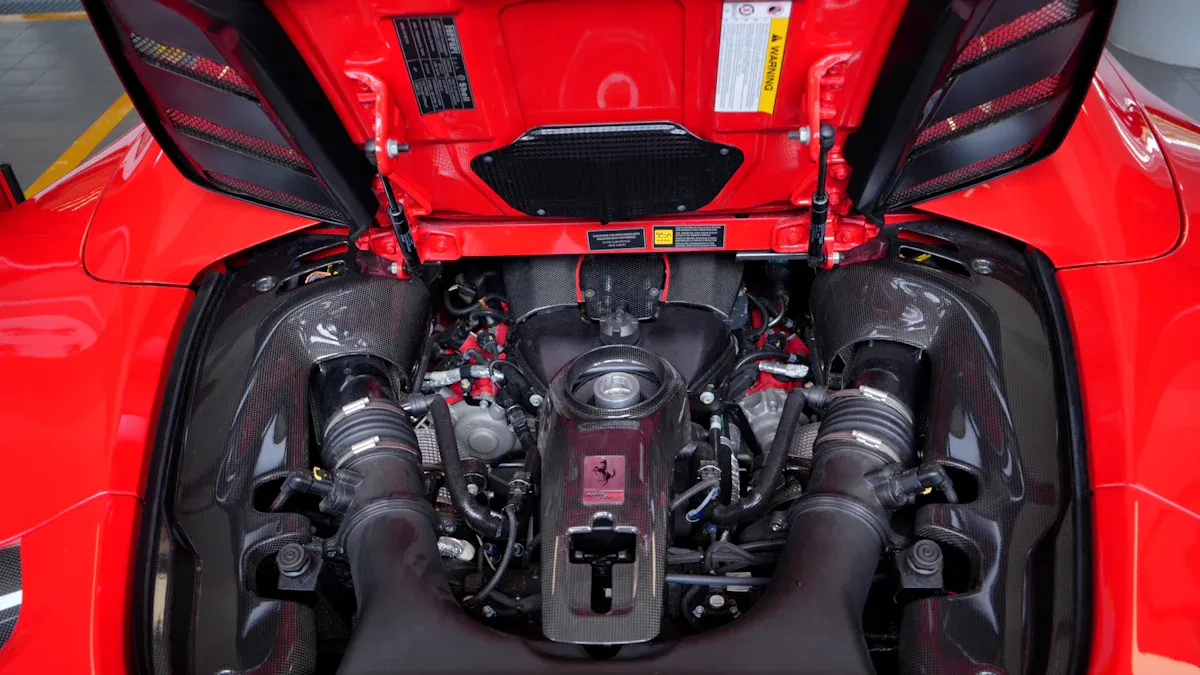

Turbochargers and Exhaust Systems

Turbochargers and exhaust systems face extreme heat and corrosive gases. TaC Coating protects these components by maintaining its properties in high-temperature environments. You’ll notice improved efficiency in turbochargers as the coating reduces thermal degradation. Exhaust systems also last longer because the coating prevents corrosion caused by exhaust gases. This makes TaC Coating an ideal choice for vehicles that demand high performance in tough conditions.

Bearings and High-Wear Parts

Bearings and other high-wear parts experience constant movement and pressure. TaC Coating enhances their performance by reducing friction and wear. You’ll find that coated bearings operate more smoothly and last longer. This is especially important in high-performance vehicles where reliability is critical. The coating also helps distribute stress evenly, preventing localized damage. With TaC Coating, you can ensure these parts perform efficiently under demanding conditions.

Comparison with Other Wear-Resistant Coatings

TaC vs. DLC Coatings

Diamond-Like Carbon (DLC) coatings are popular for their low friction and wear resistance. However, TaC Coating offers superior hardness, making it more effective in high-pressure environments. You’ll find that DLC coatings excel in applications requiring smooth surfaces, such as gears or sliding components. In contrast, TaC Coating performs better under extreme heat and mechanical stress. Its ability to resist thermal degradation gives it an edge in high-performance automotive systems. While both coatings reduce wear, TaC Coating provides greater durability in demanding conditions.

TaC vs. Ceramic Coatings

Ceramic coatings are known for their heat resistance and lightweight properties. They work well in applications like exhaust systems. However, TaC Coating surpasses ceramic coatings in hardness and wear resistance. You’ll notice that ceramic coatings can crack under heavy loads or impact, while TaC Coating maintains its integrity. Additionally, TaC Coating offers better adhesion to metal surfaces, ensuring long-lasting protection. This makes it a more reliable choice for components exposed to both mechanical stress and high temperatures.

Cost-Effectiveness and Performance

When comparing cost and performance, TaC Coating provides excellent value. Its durability reduces the need for frequent replacements, saving you money over time. While the initial cost may be higher than some alternatives, the long-term benefits outweigh the expense. You’ll also benefit from reduced maintenance and improved efficiency. TaC Coating ensures your automotive components perform reliably, even in the most challenging conditions.

Benefits of TaC Coating in Automotive Applications

Enhanced Durability and Longevity

You want your automotive components to last longer and perform reliably. TaC Coating delivers unmatched durability by protecting parts from wear and tear. Its extreme hardness shields surfaces from scratches and deformation, even under heavy loads. This coating also resists thermal degradation, ensuring components maintain their integrity in high-temperature environments. For example, engine parts coated with TaC experience less friction, which reduces damage over time. By using TaC Coating, you extend the lifespan of critical components and reduce the frequency of replacements.

Note: Longer-lasting components mean fewer interruptions and more time on the road.

Improved Performance Under Stress

High-performance vehicles often operate under intense conditions. TaC Coating enhances the reliability of components by reducing friction and wear during operation. You’ll notice smoother performance in parts like bearings and pistons, even when exposed to constant movement or pressure. The coating’s ability to distribute stress evenly prevents localized damage, ensuring parts function efficiently. Whether you’re driving at high speeds or navigating rough terrain, TaC Coating keeps your vehicle performing at its best.

Cost Savings and Maintenance Reduction

Frequent repairs and replacements can strain your budget. TaC Coating minimizes these costs by improving the durability of automotive components. You save money on maintenance because coated parts resist wear and last longer. The coating also boosts efficiency, reducing energy loss caused by friction. Over time, these benefits add up, making TaC Coating a cost-effective solution for high-performance vehicles.

Tipp: Investing in TaC Coating upfront can lead to significant savings in the long run.

TaC Coating revolutionizes wear resistance in automotive components. You gain unmatched durability and performance, even in extreme conditions. Its hardness and thermal stability protect parts from wear and heat. As automotive technology advances, this coating ensures your vehicle components remain reliable and efficient, making it a vital innovation for the future.

FAQ

What makes TaC coating better than traditional coatings?

TaC coating offers superior hardness, thermal stability, and wear resistance. You’ll notice it performs better under extreme conditions compared to traditional coatings like DLC or ceramic.

Can TaC coating be applied to all automotive components?

TaC coating works best on high-wear parts like pistons, bearings, and turbochargers. You should consult experts to determine compatibility with specific components.

How does TaC coating reduce maintenance costs?

TaC coating minimizes wear and extends component lifespan. You’ll save money by reducing the frequency of repairs and replacements, especially in high-performance vehicles.