Mining industrial telephones are rugged communication devices designed for extreme mining environments. These mining industrial telephones are built to withstand dust, moisture, and vibrations, ensuring reliable communication underground or in remote areas. Additionally, the waterproof industrial telephone models provide extra protection against water damage, making them ideal for various conditions. These devices, including marine industrial telephones, play a vital role in mining operations by improving safety, reducing downtime, and cutting costs. For instance, effective communication can lower emergency response times by over 30%, saving lives and boosting efficiency. Furthermore, the rainproof weatherproof telephone options ensure that communication remains uninterrupted even in harsh weather conditions.

Challenges in Mining Operations

Mining operations face numerous challenges that can disrupt productivity and compromise safety. These challenges often stem from communication barriers, safety risks, and operational inefficiencies. Let’s explore these issues in detail.

Communication Barriers in Remote and Underground Locations

Effective communication is critical in mining, but remote and underground locations make it difficult to maintain reliable connections. A Canadian mining company, for example, struggled with bandwidth limitations in its VSAT system, which hindered operational continuity and crew safety. Underground environments generate high volumes of data, requiring robust digital networks. Traditional wired systems often fail during emergencies, prompting a shift toward wireless technologies like RFID and through-the-earth communication. These advancements aim to overcome geographical constraints and ensure seamless communication.

Safety Risks in Hazardous Mining Environments

Mining remains one of the most dangerous industries. A review of non-coal underground mines in China from 2000 to 2021 revealed 31 major accidents, resulting in 642 fatalities. These incidents highlight the persistent safety risks miners face daily. Hazardous conditions, such as gas leaks, equipment failures, and collapses, demand immediate communication solutions. Mining industrial telephones play a vital role in emergency response, enabling quick action to prevent further harm.

Operational Inefficiencies and Downtime

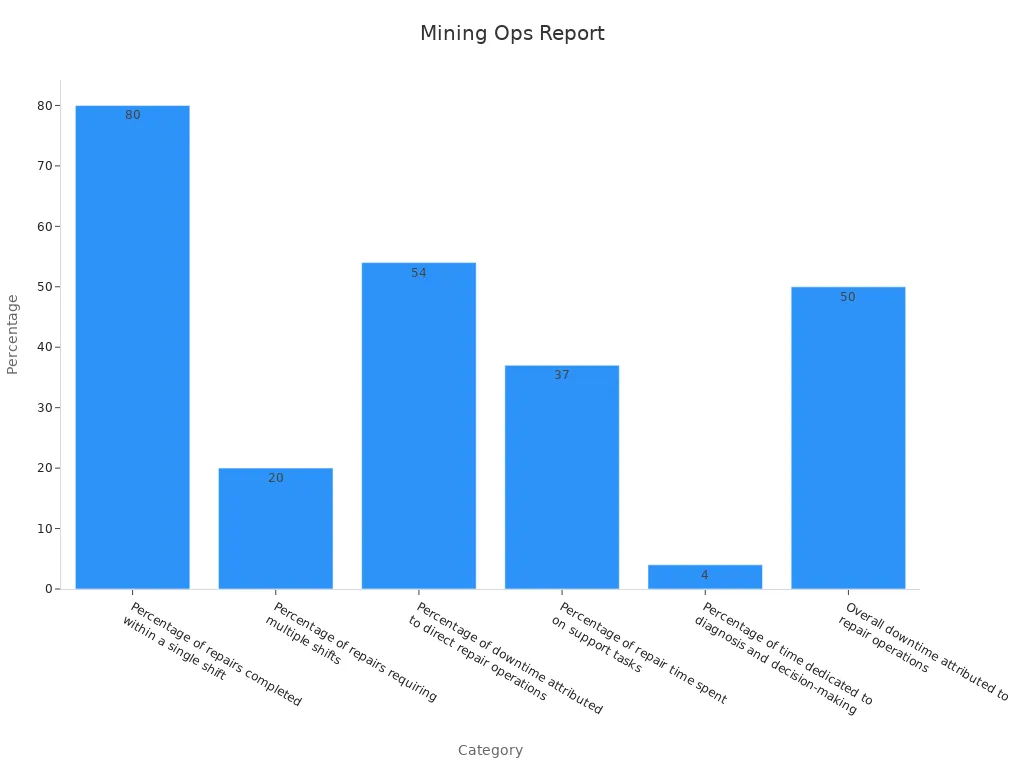

Operational inefficiencies can lead to significant downtime, impacting productivity and profitability. For instance, a study on the Sarcheshmeh Copper Mine showed that only 54% of downtime was due to direct repairs, while 46% was spent on support tasks like diagnosis and decision-making. This inefficiency underscores the need for streamlined processes and advanced communication tools.

By addressing these challenges, mining operations can enhance safety, reduce costs, and improve overall efficiency.

Applications of Mining Industrial Telephones

Mining industrial telephones have become indispensable tools in modern mining operations. Their applications extend beyond basic communication, addressing critical needs like emergency response, production monitoring, and integration with advanced technologies.

Emergency Communication and Incident Response

In emergencies, every second counts. Mining industrial telephones provide reliable two-way communication in hazardous environments, ensuring safety and quick response times. These devices reduce downtime and enhance rescue efforts during incidents like injuries, entrapments, or equipment failures.

- VoIP mining telephones play a vital role in mine site rescues, connecting miners with the control room for immediate assistance.

- Refuge Bays, which serve as emergency evacuation rooms, are equipped with robust telephones to ensure communication during evacuations.

- Signaling systems near mining shafts allow miners to communicate with elevator operators, enabling safe transport during emergencies.

By strategically placing these telephones throughout mining sites, operators can significantly improve emergency preparedness and response.

Production Monitoring and Coordination

Mining operations rely on seamless coordination to maintain productivity. Mining industrial telephones enable real-time communication between teams, ensuring smooth workflows. For example, supervisors can use these devices to monitor production levels and address issues immediately. This reduces delays and keeps operations running efficiently.

Additionally, these telephones help coordinate tasks across large sites, bridging the gap between underground workers and surface teams. This level of connectivity minimizes miscommunication and boosts overall productivity.

Integration with Modern Technologies (VoIP, IoT, and Smart Systems)

The integration of mining industrial telephones with modern technologies has revolutionized mining communication. VoIP systems, for instance, use existing LAN/IP networks, making them cost-efficient and easy to install. These telephones also support protocols like Modbus TCP and SNMP, allowing seamless integration with SCADA systems and other IT infrastructure.

| Feature | Description |

|---|---|

| VoIP Integration | Installed along fiber optic networks, enabling communication with control rooms. |

| Self-Monitoring | Alerts control room staff of connectivity issues, enhancing safety. |

| Remote Management | Allows updates and maintenance from the control room, reducing costs. |

By incorporating IoT and smart systems, mining industrial telephones now offer remote management and self-monitoring capabilities. These advancements not only improve safety but also streamline operations, making them essential for the future of mining.

Advancements in Mining Industrial Telephones by 2025

Enhanced Durability and Resistance to Harsh Conditions

Mining environments are unforgiving, with extreme temperatures, dust, and moisture posing constant challenges. By 2025, mining industrial telephones will feature cutting-edge durability enhancements to withstand these conditions. For instance, devices will include IP65-rated weather resistance, ensuring protection against dust and water. They’ll also operate in temperatures ranging from -20 to +55 degrees Celsius, making them reliable in both freezing and sweltering conditions.

| Feature | Description |

|---|---|

| Weather Resistance | IP65 rating ensures dust and water resistance. |

| Condensation Proof | Prevents internal water formation that could impair performance. |

| Corrosion Resistance | Coated aluminum bodies resist geothermal gases like sulfur and hydroperoxide. |

These advancements mean fewer breakdowns and longer lifespans, reducing maintenance costs and ensuring uninterrupted communication.

Improved Connectivity in Remote and Underground Areas

Reliable communication in remote and underground locations has always been a challenge. By 2025, mining industrial telephones will leverage advanced technologies to bridge this gap. Features like Low Energy Proximity Wireless (LEPW) will enable tracking, text messaging, and gas monitoring in underground areas. Additionally, Ethernet network support will enhance equipment monitoring and control, improving both safety and efficiency.

- Self-monitoring capabilities will ensure maximum uptime by detecting faults early.

- Quality of Service (QoS) features will prioritize network traffic, ensuring clear voice and data transmission.

- Remote maintenance will reduce costs and downtime, making these systems more efficient than ever.

These improvements will make mining operations safer and more productive, even in the most challenging environments.

Integration with Smart Mining Systems and Automation

The future of mining lies in automation, and mining industrial telephones will play a key role in this transformation. By 2025, these devices will seamlessly integrate with smart mining systems, enabling real-time data sharing and coordination. For example, VoIP mining telephones will connect underground workers with control rooms, enhancing safety and operational efficiency.

| Evidence Type | Description |

|---|---|

| Autonomous Haulage System | Self-driving vehicles with sensors and GPS for real-time data management. |

| Wireless Networks | Tracks equipment and personnel, improving connectivity and safety underground. |

These integrations will not only streamline operations but also pave the way for fully automated mining processes, reducing human risk and increasing efficiency.

Mining industrial telephones have revolutionized mining operations by enhancing safety, streamlining communication, and boosting efficiency. By 2025, advancements in durability, connectivity, and smart integration will redefine their role in the industry.

| Objective | Description |

|---|---|

| Increase Production Output | Speed up drilling and remove bottlenecks to deliver metals quicker to the surface. |

| Reduce Operational Costs | Save costs through automation and efficient maintenance strategies. |

| Improve Safety | Minimize risks of injuries and fatalities with effective communication systems. |

These innovations will empower mining companies to operate smarter, safer, and faster, transforming the industry for years to come.

FAQ

What makes mining industrial telephones different from regular phones?

Mining industrial telephones are built for harsh environments. They resist dust, water, and extreme temperatures, ensuring reliable communication in underground or remote mining locations. 🛠️

Can mining industrial telephones work without internet?

Yes, many models use analog or wired systems. However, advanced versions with VoIP require internet for features like remote monitoring and smart system integration.

How do these phones improve mining safety?

They provide instant communication during emergencies. Features like gas monitoring, self-diagnostics, and integration with rescue systems help protect workers and reduce risks. 🚨