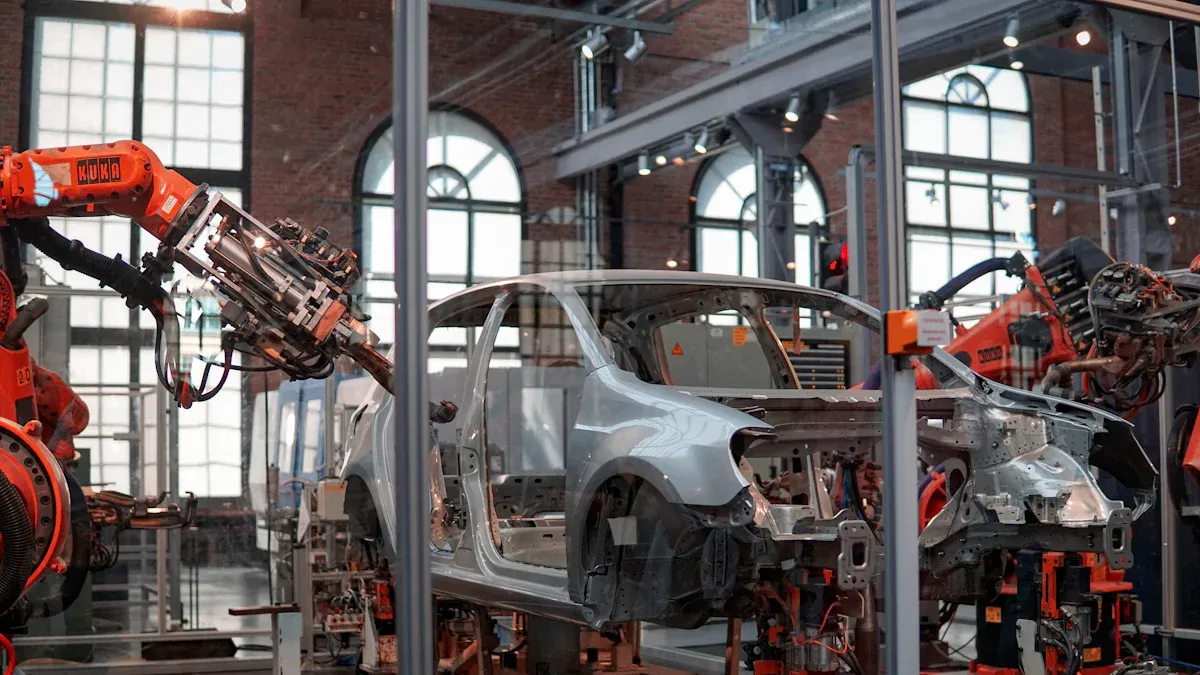

The automotive industry constantly evolves to meet higher standards of durability, performance, and sustainability. TAC Coating plays a vital role in this transformation. You can see its impact in components designed to last longer, perform better, and reduce environmental harm. It offers solutions to industry challenges, making vehicles more reliable and efficient.

キーテイクアウト

- TAC Coating makes car parts last longer by stopping wear. This means fewer repairs and less money spent on fixing them.

- コーティング handles heat well and reduces friction. It helps cars work better in very hot or cold weather.

- TAC Coating helps make lighter cars. Lighter cars use less fuel and pollute less, helping the environment.

Understanding TAC Coating

What is TAC Coating?

TAC Coating, short for Tetrahedral Amorphous Carbon Coating, is a thin, protective layer applied to various surfaces. It is known for its exceptional hardness and low friction. You can think of it as a shield that enhances the performance and lifespan of materials. This coating is made from carbon atoms arranged in a unique structure, giving it remarkable strength and durability. It is widely used in industries where components face extreme wear and tear, especially in automotive manufacturing.

Key Properties of TAC Coating

ツイート コーティングはそれが原因で際立っています unique properties. It offers high hardness, which protects surfaces from scratches and damage. Its low friction reduces wear, making moving parts last longer. The coating also resists heat, ensuring stable performance in high-temperature environments. Additionally, it is lightweight, which makes it ideal for modern automotive designs. These properties make TAC Coating a preferred choice for improving the reliability of automotive components.

Applications in Automotive Components

You will find TAC Coating in many automotive parts. It is commonly used on engine components like pistons and camshafts to reduce friction and improve efficiency. It also protects gears and bearings, ensuring smooth operation over time. In electric vehicles, TAC Coating plays a crucial role in enhancing the performance of battery systems and electric motors. Its versatility makes it an essential material in the automotive industry.

Benefits of TAC Coating in Automotive Components

Enhanced Durability and Wear Resistance

When it comes to durability, TAC Coating stands out as a game-changer. You often see automotive components wear down due to constant friction and pressure. TAC Coating creates a protective layer that reduces this wear, extending the lifespan of parts like pistons, gears, and bearings. Its hardness acts as a shield, preventing scratches and surface damage. This means fewer replacements and repairs, saving both time and money.

ヒント: By choosing materials with TAC Coating, manufacturers can ensure vehicles perform reliably over longer periods.

Performance in Extreme Conditions

Automotive components face harsh environments, from scorching heat to freezing temperatures. TAC Coating ensures these parts maintain their performance under such conditions. Its heat resistance allows engine components to function smoothly even at high temperatures. Similarly, its stability in cold environments prevents cracking or weakening. Whether you’re driving through a desert or a snowy mountain, TAC Coating helps your vehicle stay dependable.

Contribution to Lightweight Designs

Modern vehicles aim to be lighter for better fuel efficiency and performance. TAC Coating plays a crucial role here. Its thin yet strong layer allows manufacturers to use lighter materials without compromising durability. For example, aluminum parts coated with TAC Coating can replace heavier steel components. This not only improves fuel economy but also reduces emissions, contributing to a greener future.

Market Trends and Innovations

Advancements in TAC Coating Technology

You might wonder how TAC Coating continues to evolve. Recent advancements focus on improving its application methods and performance. Researchers have developed more efficient deposition techniques, like plasma-enhanced chemical vapor deposition (PECVD). These methods create thinner, more uniform coatings, which enhance durability and reduce material waste. Innovations also aim to improve the coating’s adhesion to different surfaces, ensuring it performs well across a variety of automotive components.

Another exciting development is the integration of nanotechnology. By incorporating nanoparticles, manufacturers can further enhance the coating’s hardness and thermal resistance. These advancements make TAC Coating even more reliable for modern automotive needs.

Adoption in Electric Vehicles

自動車業界を変革する電気自動車(EV) TAC Coating plays a key role in this shift. You’ll find it in critical EV components like electric motors, battery systems, and powertrain parts. Its low friction and heat resistance improve the efficiency of these systems, helping EVs achieve better performance and longer lifespans.

TAC Coating also supports the lightweight designs of EVs. By enabling the use of lighter materials, it helps manufacturers reduce vehicle weight, which directly impacts energy efficiency. As EV adoption grows, the demand for TAC Coating will likely increase.

Emerging Applications in Automotive Manufacturing

TAC Coating is no longer limited to traditional automotive parts. You’ll see it being used in innovative ways, such as in advanced safety systems and autonomous vehicle sensors. For example, it protects LiDAR and camera lenses from scratches and environmental damage, ensuring these systems function reliably.

Manufacturers are also exploring its use in 3D-printed automotive parts. TAC Coating enhances the durability of these components, making them suitable for real-world applications. These emerging uses highlight the versatility and growing importance of TAC Coating in the automotive sector.

Factors Driving Adoption

Demand for High-Performance Materials

The automotive industry constantly seeks materials that can handle tough conditions. You need components that last longer, resist wear, and perform well under stress. TAC Coating meets these demands by offering exceptional hardness and low friction. It protects parts like gears and pistons from damage, ensuring they work efficiently over time. This makes it a preferred choice for manufacturers aiming to build reliable vehicles.

Did you know? Using high-performance materials like TAC Coating can reduce maintenance costs and improve vehicle longevity.

Growth of Electric Vehicles

Electric vehicles (EVs) are becoming more popular as people look for eco-friendly transportation. You’ll notice that EVs require lightweight and efficient components to maximize battery life. TAC Coating plays a key role here. It allows manufacturers to use lighter materials without sacrificing durability. It also improves the performance of electric motors and battery systems by reducing friction and heat. As EV adoption grows, the demand for this advanced coating will continue to rise.

Focus on Advanced Safety Systems

Modern vehicles rely on advanced safety systems to protect passengers. These systems include sensors, cameras, and LiDAR technology. You’ll find TAC Coating used to protect these sensitive components. It prevents scratches and damage caused by harsh environments, ensuring safety features work reliably. This makes it an essential material for manufacturers focused on improving vehicle safety.

Challenges in Adoption

High Costs of TAC Coating

One of the biggest challenges you might notice with TAC Coating is its high cost. The advanced materials and specialized equipment required for its application make it expensive. For manufacturers, this can increase production costs significantly. Smaller companies, in particular, may find it difficult to afford this technology.

Did you know? The cost of TAC Coating can sometimes be higher than the base material it protects.

To address this, researchers are working on cost-effective methods to produce and apply TAC Coating. However, until these solutions become widely available, the high price remains a barrier to its adoption.

Technological Barriers

Applying TAC Coating requires advanced technology and expertise. You need precise equipment to ensure the coating adheres properly and performs as expected. This can be a challenge for manufacturers without access to such resources.

Additionally, not all materials are compatible with TAC Coating. Some surfaces may require extra preparation, which adds complexity to the process. These technological hurdles can slow down the adoption of TAC Coating, especially in regions with limited access to cutting-edge manufacturing tools.

Competition with Alternative Coatings

TAC Coating faces stiff competition from other protective coatings. Options like diamond-like carbon (DLC) coatings and ceramic coatings offer similar benefits at potentially lower costs. You might see manufacturers choosing these alternatives to save money or simplify production.

ヒント: When selecting a coating, consider factors like cost, performance, and compatibility with your materials.

While TAC Coating offers unique advantages, its competitors continue to challenge its dominance in the automotive industry.

Regional Insights

North America’s Innovation Leadership

You’ll notice North America leading the charge in TAC Coating innovation. The region invests heavily in research and development, driving advancements in coating technologies. Companies here focus on improving application methods and exploring new uses for TAC Coating in automotive components.

Note: North America’s strong collaboration between manufacturers and research institutions accelerates innovation.

The region also benefits from a robust automotive market. Major automakers adopt TAC Coating to enhance vehicle performance and durability. This creates a competitive environment where innovation thrives. You’ll see North America setting benchmarks for TAC Coating applications globally.

Asia Pacific’s Manufacturing Growth

Asia Pacific dominates automotive manufacturing, and TAC Coating plays a growing role in this success. Countries like China, Japan, and South Korea lead in producing vehicles equipped with advanced materials. Manufacturers here prioritize cost-effective solutions, making TAC Coating more accessible.

You’ll find Asia Pacific leveraging its large-scale production capabilities to integrate TAC Coating into various components. This region also benefits from a skilled workforce and advanced manufacturing technologies.

ヒント: Asia Pacific’s focus on efficiency and affordability makes it a key player in TAC Coating adoption.

Europe’s Sustainability Focus

Europe stands out for its commitment to sustainability. You’ll see automakers here using TAC Coating to reduce environmental impact. Lightweight designs enabled by TAC Coating improve fuel efficiency and lower emissions.

Did you know? Europe’s strict environmental regulations drive innovation in eco-friendly materials like TAC Coating.

The region also invests in electric vehicles, where TAC Coating enhances battery systems and lightweight components. Europe’s focus on green technology positions it as a leader in sustainable automotive manufacturing.

Future Outlook for TAC Coating

Revolutionizing Automotive Components

TAC Coating is set to redefine how automotive components perform. You will see it enabling parts to last longer and work more efficiently. Its ability to reduce wear and friction ensures that engines, gears, and other critical components operate smoothly over time. This coating also supports the shift toward lightweight materials, which improves fuel efficiency and reduces emissions. As manufacturers continue to innovate, TAC Coating will likely become a standard in producing high-performance vehicles.

Supporting Next-Generation Technologies

The future of TAC Coating lies in its role in next-generation automotive technologies. You’ll notice its growing importance in electric vehicles, where it enhances battery systems and electric motors. It also plays a key role in autonomous vehicles by protecting sensors and cameras from damage. Researchers are exploring how TAC Coating can integrate with smart materials, enabling vehicles to adapt to changing conditions. These advancements will make cars safer, more efficient, and better equipped for the future.

Market Growth Predictions

The demand for TAC Coating is expected to rise significantly. You can attribute this growth to the increasing adoption of electric and autonomous vehicles. The global push for サステナビリティ also drives its use in lightweight designs. Analysts predict that the TAC Coating market will expand as manufacturers seek durable and eco-friendly solutions. With ongoing research and development, you can expect this technology to become more accessible and cost-effective, further fueling its adoption.

TAC Coating has transformed automotive components by enhancing durability, efficiency, and sustainability. You can see its impact in lightweight designs and advanced safety systems. Its potential to drive innovation in electric and autonomous vehicles remains unmatched. Continued research and investment will ensure this technology keeps shaping the future of the automotive industry.

よくある質問

What makes TAC Coating different from other coatings?

TAC Coating offers unmatched hardness, low friction, and heat resistance. These properties make it ideal for automotive components that face extreme wear and harsh conditions.

Can TAC Coating improve electric vehicle performance?

Yes! TAC Coating reduces friction and heat in electric motors and battery systems. This improves efficiency, extends lifespan, and supports lightweight designs for better energy savings.

Is TAC Coating environmentally friendly?

✅ Absolutely! TAC Coating enables lightweight designs, reducing fuel consumption and emissions. Its durability also minimizes waste by extending the lifespan of automotive components.