Waterproof tunnel telephones play a vital role in ensuring safety and communication in harsh environments like tunnels, highways, and industrial sites. These IP tunnel telephones are designed to withstand extreme conditions, but regular maintenance is key to keeping them reliable. For example, inspecting seals, cleaning units, and checking wiring every six months can prevent failures. Proper care, like applying anti-corrosion spray or replacing damaged parts, extends their lifespan. Whether it’s a public tunnel telephone or an emergency tunnel telephone, consistent upkeep ensures they remain functional when needed most.

Regular Cleaning and Proper Tools

Importance of Cleaning Waterproof Tunnel Telephones

Keeping a waterproof tunnel telephone clean is essential for its performance and longevity. Dust, debris, and grime can accumulate over time, especially in harsh environments like tunnels or industrial sites. This buildup can damage seals, compromise waterproofing, and reduce the device’s efficiency. Regular cleaning prevents these issues and ensures the telephone remains functional when needed most. It also helps maintain the device’s weatherproof integrity, which is critical in challenging conditions. Neglecting this simple maintenance step could lead to costly repairs or replacements.

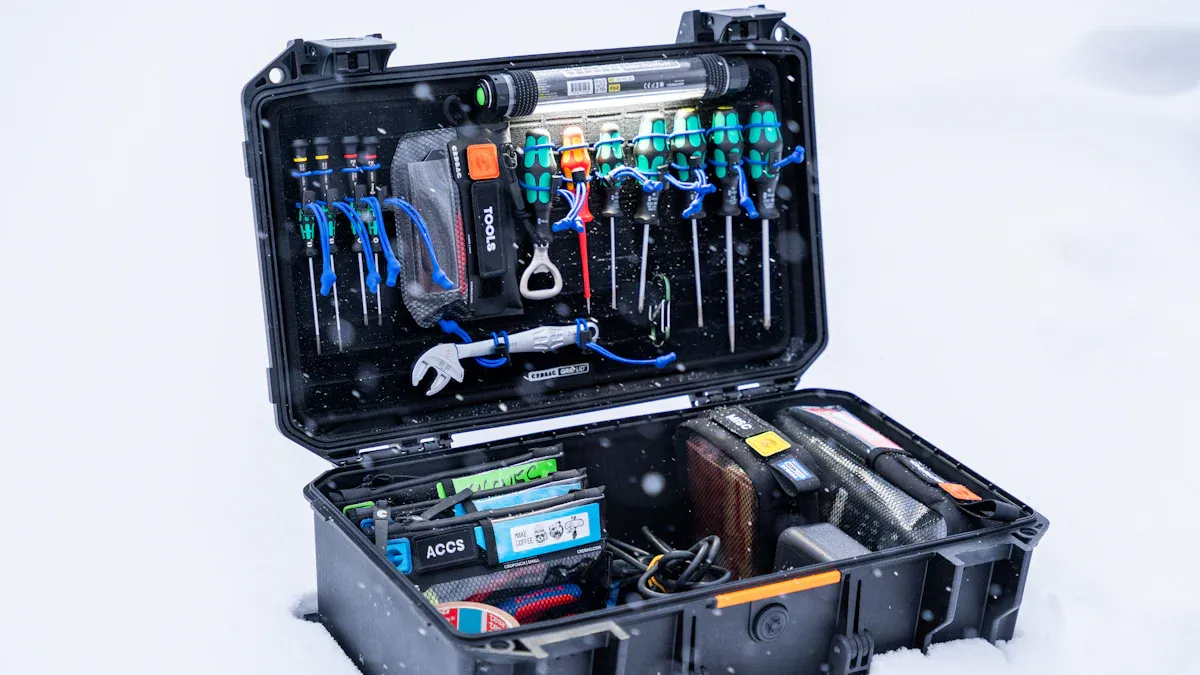

Recommended Tools for Cleaning

Using the right tools makes cleaning a waterproof tunnel telephone both safe and effective. Here’s a quick guide to the recommended tools:

| Specification | Description |

|---|---|

| Cleaning Material | Soft microfiber cloths to avoid scratching the surface. |

| Cleaning Tools | A small, soft-bristled brush for cleaning crevices. |

| Cleaning Solution | Mild soap solutions or non-abrasive cleaners for tough stains. |

| Avoided Materials | Avoid harsh chemicals like alcohol, ammonia, or bleach to protect the device. |

| Cleaning Method | Apply cleaning solution to the cloth, not directly on the device, to prevent damage. |

| Drying Method | Use a clean, dry cloth to remove moisture and maintain waterproof seals. |

These tools ensure the device stays in top condition without risking damage to its sensitive components.

Best Practices for Cleaning Without Damage

Cleaning a waterproof tunnel telephone requires care to avoid causing harm. Start by wiping the surface with a soft microfiber cloth to remove dust and dirt. For stubborn spots, use a soft-bristled brush with a mild soap solution. Always apply the cleaning solution to the cloth, not directly on the device, to prevent moisture from seeping into sensitive areas. After cleaning, dry the telephone thoroughly with a clean cloth to maintain its waterproof seals. These simple steps keep the device clean and functional without compromising its durability.

Inspecting and Maintaining Seals and Gaskets

Role of Seals in Waterproofing

Seals and gaskets are the unsung heroes of a waterproof tunnel telephone. They act as the first line of defense against water and dust. Without them, moisture could seep into the device, causing serious damage. Regular inspections help ensure these components stay intact. Cracks, tears, or any signs of wear can compromise the waterproof barrier. Replacing damaged seals immediately keeps the device safe and functional in harsh environments.

Identifying Wear and Tear in Seals

Spotting damage early can save time and money. Regularly check seals and gaskets for cracks, brittleness, or other signs of deterioration. If a seal looks worn or feels less flexible, it’s time for a replacement. Even small imperfections can lead to big problems. A quick inspection every few months ensures the device remains waterproof and ready for use.

Steps to Replace or Repair Seals

Replacing a seal is easier than it sounds. First, remove the old, damaged seal carefully to avoid scratching the device. Clean the area thoroughly to remove any debris. Next, install the new seal, ensuring it fits snugly and evenly. For minor damage, repair kits can patch small cracks. However, replacing the seal is often the best option for long-term reliability. These steps help maintain the waterproof integrity of the telephone, ensuring it performs well in any environment.

Protecting Against Corrosion and Environmental Damage

Environmental Factors That Cause Corrosion

Corrosion is a common enemy of devices exposed to harsh environments. Waterproof tunnel telephones often face challenges like high humidity, salty air, and temperature fluctuations. These factors accelerate rust and material degradation, especially in tunnels near coastal areas or industrial zones. Over time, corrosion can weaken the device’s structure and compromise its waterproofing. Regular checks and preventive measures are essential to combat these environmental threats.

Applying Anti-Corrosion Treatments

Preventing corrosion starts with the right treatments. Applying anti-corrosion sprays to metal components creates a protective barrier against moisture. For example, the American Galvanizers Association highlights that hot-dip galvanizing could have saved the Golden Gate Bridge up to $1 billion in maintenance costs. While galvanizing may not apply to telephones, similar protective coatings can significantly reduce wear and tear. Regularly reapplying these treatments ensures long-term durability, especially in humid or salty environments.

Tip: Always clean the device thoroughly before applying any anti-corrosion treatment. This ensures the coating adheres properly and provides maximum protection.

Proper Storage to Prevent Damage

Proper storage plays a big role in protecting waterproof tunnel telephones from environmental damage. Here are some effective practices:

- Seal installation edges and wiring with silicone sealant to create a watertight barrier.

- Inspect seals and gaskets regularly to maintain weatherproofing.

- Apply a fresh layer of silicone sealant annually and use anti-corrosion spray on metal parts in humid areas.

These steps help keep the device safe from moisture and corrosion, ensuring it stays functional for years.

Avoiding Extreme Temperatures and Physical Stress

Effects of Extreme Temperatures on Waterproof Tunnel Telephones

Extreme temperatures can significantly impact the performance of a waterproof tunnel telephone. Devices exposed to intense heat or freezing cold may experience material degradation, reduced efficiency, or even complete failure. These telephones are often used in industrial settings where maintaining reliable communication is critical.

- High temperatures can cause internal components to overheat, leading to malfunctions.

- Freezing conditions may make seals brittle, compromising waterproofing.

- Temperature fluctuations can weaken the device’s structure over time.

The Jiuwo Waterproof Telephone, for instance, is built to operate in temperatures ranging from -20°C to 60°C. Its rugged design ensures durability in harsh environments, making it a dependable choice for tunnels and industrial sites.

| Feature | Details |

|---|---|

| Waterproof Rating | IP67 |

| Operational Temperature Range | -20°C to 60°C |

| Suitable Environments | Wet or humid conditions |

Shielding Devices from Physical Stress

Physical stress, such as impacts or vibrations, can damage a waterproof tunnel telephone. Heavy machinery, falling debris, or accidental collisions are common risks in tunnels and industrial areas. To minimize damage:

- Install devices away from high-traffic zones.

- Use shock-absorbing mounts to reduce vibrations.

- Regularly inspect for dents or cracks that could compromise waterproofing.

These precautions help maintain the device’s integrity and ensure uninterrupted communication.

Using Protective Enclosures in High-Risk Areas

Protective enclosures are essential for safeguarding telephones in extreme environments. The Jiuwo Waterproof Telephone, for example, features an IP67-rated design that shields it from water, dust, and physical impacts. This makes it ideal for tunnels, oil refineries, and chemical plants.

| Feature | Description |

|---|---|

| Robust Design | Protects devices from rain, snow, and dust, ensuring functionality. |

| IP65 Rating | Shields internal components from water and dust, ideal for industrial sites. |

| Durability | Cold rolled steel construction resists physical impacts in high-risk areas. |

These enclosures not only extend the lifespan of the device but also ensure reliable communication during emergencies, where every second counts.

Conducting Routine Inspections and Repairs

Benefits of Regular Inspections

Routine inspections are the backbone of maintaining a waterproof tunnel telephone. They ensure the device stays reliable and functional in demanding environments. Regular checks help identify issues early, preventing costly repairs and downtime. According to the Federal Highway Administration (FHWA), inspecting these devices every 24 months is ideal. This interval aligns with protocols used for tunnels and bridges, offering flexibility based on specific conditions.

Inspections also provide long-term benefits supported by data:

| Benefit Type | Description |

|---|---|

| Uniform Inspection Practices | Establishes consistent methods across states, improving analysis of tunnel conditions. |

| Greater Accountability | Mandated reporting increases visibility and transparency regarding tunnel conditions. |

| Informed Decision-Making | Data allows for better project and policy choices related to tunnel maintenance and repairs. |

| Early Problem Detection | Helps in identifying issues early, increasing the longevity of tunnel assets and avoiding costly repairs. |

| Cost Savings | Preventative maintenance is more cost-effective than reactive repairs, preserving structural integrity. |

These benefits highlight why inspections are essential for maximizing the operational lifespan of tunnel telephones.

Checklist for Routine Maintenance

A simple checklist can make routine maintenance more effective. Here’s what to include:

- Visual Inspection: Check for cracks, dents, or signs of wear on the device’s exterior.

- Seal and Gasket Check: Ensure seals are intact and free from brittleness or tears.

- Corrosion Assessment: Look for rust or discoloration on metal components.

- Functional Test: Verify the telephone’s audio clarity and button responsiveness.

- Cleaning: Remove dust and debris using recommended tools and solutions.

Following this checklist ensures the waterproof tunnel telephone remains in top condition.

When to Seek Professional Repairs

Sometimes, repairs require professional expertise. Knowing when to call for help can save time and prevent further damage. Performance indicators like MTBF (Mean Time Between Failures) and MTTR (Mean Time to Repair) offer valuable insights. If failures occur more frequently or repairs take longer than expected, it’s time to consult a technician.

| Indicator | Description |

|---|---|

| MTBF | Measures the reliability of a system or component, calculated as the average time between failures. |

| MTTR | Indicates the average time taken to repair a system or component after a failure. |

| PMP | Represents the percentage of maintenance work that is planned versus unplanned, indicating the effectiveness of the maintenance program. |

Professional repairs ensure the device’s reliability and extend its lifespan, especially in high-risk environments.

Maintaining a waterproof tunnel telephone involves five essential steps that ensure its reliability and longevity. Proper cleaning, seal inspections, corrosion prevention, temperature management, and routine checks all play a critical role. Each tip contributes to the device’s performance, as shown below:

| Maintenance Tip | Significance |

|---|---|

| Proper Installation | Ensures secure connections and functionality of the telephone. |

| Sealing for Weatherproofing | Creates a watertight barrier, preventing moisture from damaging the unit. |

| Securing the Installation | Prevents wobbling or shifting, maintaining functionality in harsh conditions. |

| Testing for Functionality | Verifies operational status, ensuring reliability during emergencies. |

| Performing Regular Maintenance | Extends lifespan by preventing minor issues from escalating into major problems. |

Consistent maintenance not only prevents costly repairs but also enhances safety. For example, routine inspections have proven to prevent failures, as seen in the I-70 Hanging Lake tunnel incident. Proactively following these tips ensures the device remains dependable in critical situations.

Tip: Regular upkeep is a small investment that guarantees long-term functionality and safety.

FAQ

How often should waterproof tunnel telephones be inspected?

Inspect these devices every six months. Regular checks help identify issues early, ensuring they remain functional and reliable in harsh environments.

Can I use any cleaning solution for waterproof tunnel telephones?

No, avoid harsh chemicals like bleach or ammonia. Use mild soap solutions or non-abrasive cleaners to protect the device’s waterproof seals and sensitive components.

What’s the best way to prevent corrosion on these telephones?

Apply anti-corrosion spray to metal parts after cleaning. This creates a protective barrier against moisture, extending the device’s lifespan in humid or salty environments.

Tip: Always clean the device thoroughly before applying any protective treatments for maximum effectiveness.