RS232 Industrial Keypads are essential components in industrial settings. These keypads are commonly used in applications that demand dependable input devices, such as an Industrial Vending MachineKeypad or an Access Control lndustrial Keypad. Known for their durability and straightforward design, they are well-suited for challenging environments. This blog explores their advantages and limitations to help you determine their practicality. Additionally, devices like an LED llluminated IndustrialKeypad highlight how these keypads are tailored to meet specialized requirements.

Key Takeaways

- RS232 Industrial Keypads are made to be durable. Their strong build works well in rough environments, staying reliable in tough situations.

- These keypads work easily with older machines. They use the RS232 protocol, making them fit well in places with old equipment.

- Though affordable and easy to use, RS232 Keypads may not work for modern needs. Their slow speed and limited growth can cause problems in advanced systems.

Understanding RS232 Industrial Keypads

What Are RS232 Industrial Keypads?

RS232 Industrial Keypads are specialized input devices designed for industrial environments. You can think of them as ruggedized versions of standard keypads, built to withstand tough conditions. These keypads use the RS232 communication protocol, which allows them to send data to connected devices. This protocol has been a reliable standard in industrial settings for decades. You often find these keypads in applications where durability and simplicity are essential.

Key Features and Capabilities

RS232 Industrial Keypads come with several features that make them stand out. Their robust construction ensures they can handle physical stress, such as heavy usage or exposure to dust and moisture. Many models include tactile feedback, which helps you confirm each keypress. They also support straightforward integration with legacy systems, thanks to the RS232 protocol. Additionally, these keypads are easy to install and maintain, making them a practical choice for many industrial applications.

Role in Industrial Applications

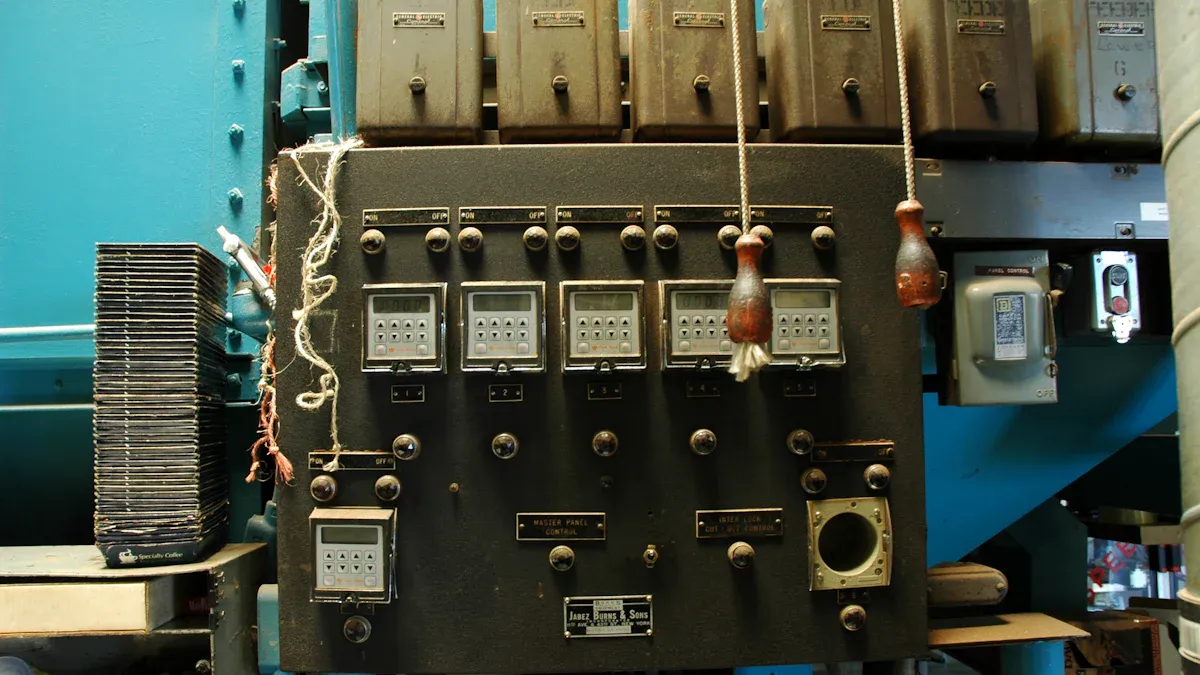

In industrial settings, RS232 Industrial Keypads play a critical role. You might see them used in machinery control panels, access control systems, or vending machines. Their reliability ensures smooth operation in environments where other input devices might fail. For example, you can rely on these keypads in factories with high levels of vibration or temperature fluctuations. Their compatibility with older systems also makes them a go-to solution for facilities that still use legacy equipment.

Strengths of RS232 Industrial Keypads

Durability and Ruggedness

You can count on RS232 Industrial Keypads to withstand tough conditions. Their rugged design makes them ideal for environments where dust, moisture, or physical impact might damage other input devices. Manufacturers often use materials like stainless steel or high-grade plastic to ensure durability. These keypads resist wear and tear even after years of heavy use. Whether you’re operating machinery in a factory or managing access control outdoors, their robust construction ensures reliable performance.

Compatibility with Legacy Systems

RS232 Industrial Keypads excel in facilities that rely on older equipment. The RS232 communication protocol has been a standard for decades, making these keypads compatible with legacy systems. You won’t need to worry about complex upgrades or compatibility issues. This feature allows you to integrate the keypad seamlessly into existing setups, saving time and resources. If your industrial environment includes older machines, these keypads provide a practical solution.

Cost-Effectiveness and Simplicity

These keypads offer a straightforward design that minimizes costs. You won’t find unnecessary features that complicate their operation. Their simplicity makes them easy to install and maintain, reducing downtime and maintenance expenses. RS232 Industrial Keypads are an affordable option for businesses that need reliable input devices without breaking the budget. Their cost-effectiveness makes them a popular choice in industries where efficiency matters.

Reliability in Harsh Environments

RS232 Industrial Keypads perform consistently in challenging conditions. Extreme temperatures, vibrations, and electrical interference won’t compromise their functionality. You can rely on them in environments where other devices might fail. Their ability to operate under harsh conditions ensures uninterrupted workflows. For industries like manufacturing or logistics, this reliability is crucial for maintaining productivity.

Weaknesses of RS232 Industrial Keypads

Limited Data Transmission Speed

The RS232 communication protocol, while reliable, operates at a slower data transmission speed compared to modern alternatives. This limitation can become a bottleneck in applications requiring rapid data exchange. If your industrial processes demand real-time communication or high-speed data transfer, an RS232 Industrial Keypad may not meet your needs. The protocol’s maximum speed, typically capped at 115.2 kbps, restricts its use in advanced systems where faster protocols like USB or Ethernet are preferred.

Susceptibility to Electrical Noise

RS232 Industrial Keypads are vulnerable to electrical noise, especially in environments with high electromagnetic interference (EMI). This interference can distort the signals transmitted through the RS232 protocol, leading to errors or communication failures. If your facility uses heavy machinery or operates near high-voltage equipment, you might encounter this issue. Shielded cables and proper grounding can mitigate the problem, but these solutions add complexity and cost to the setup.

Lack of Scalability for Modern Systems

The RS232 protocol supports only point-to-point communication, which limits its scalability. You cannot easily connect multiple devices to a single RS232 Industrial Keypad without additional hardware. This restriction makes it less suitable for modern industrial systems that require networked or multi-device setups. If your operations involve interconnected devices or IoT integration, you may find RS232 keypads inadequate.

Risk of Obsolescence in Advanced Applications

As technology evolves, the RS232 protocol faces the risk of obsolescence. Many modern systems no longer include RS232 ports, favoring newer interfaces like USB or wireless connectivity. While RS232 Industrial Keypads remain functional in legacy systems, their relevance diminishes in cutting-edge applications. If your industry adopts advanced technologies, transitioning away from RS232-based devices may become inevitable.

Practical Applications of RS232 Industrial Keypads

Ideal Use Cases in Industrial Settings

RS232 Industrial Keypads work best in environments where durability and simplicity are essential. You can use them in factories, warehouses, or outdoor facilities where conditions are harsh. For example, they are ideal for controlling heavy machinery or managing access to restricted areas. Their rugged design ensures they can handle dust, moisture, and frequent use without failing. If your operations rely on legacy systems, these keypads integrate seamlessly, making them a practical choice for older setups.

Scenarios Where RS232 Keypads Excel

These keypads excel in applications that demand reliability over speed. You might find them in industrial vending machines, where they provide consistent performance. They also shine in environments with high vibrations or temperature changes, such as manufacturing plants. Their straightforward design reduces the risk of errors, ensuring smooth operation. If you need a dependable input device for repetitive tasks, an RS232 Industrial Keypad delivers excellent results.

Limitations in Modern Industrial Systems

While RS232 Industrial Keypads perform well in traditional setups, they struggle in modern systems. Their limited data transmission speed and lack of scalability make them less suitable for advanced applications. For instance, industries adopting IoT or networked devices may find these keypads outdated. If your operations require high-speed communication or multi-device integration, you might need to explore more advanced alternatives.

RS232 Industrial Keypads offer durability, simplicity, and compatibility with legacy systems, making them reliable in harsh environments. However, their limited speed and scalability may hinder modern applications. You should consider these keypads if your operations prioritize ruggedness and cost-effectiveness over advanced features. Evaluate your system’s needs to make the best choice.

제품 정보

What makes RS232 Industrial Keypads different from standard keypads?

RS232 Industrial Keypads are built for durability. They withstand harsh conditions like dust, moisture, and vibrations. Their compatibility with legacy systems also sets them apart.

Can RS232 Industrial Keypads work with modern systems?

They can work with modern systems using adapters. However, their limited scalability and slower data speeds may not meet advanced system requirements.

How do you maintain RS232 Industrial Keypads?

Clean them regularly with a soft cloth. Avoid harsh chemicals. Inspect cables and connections to ensure proper functionality in industrial environments.