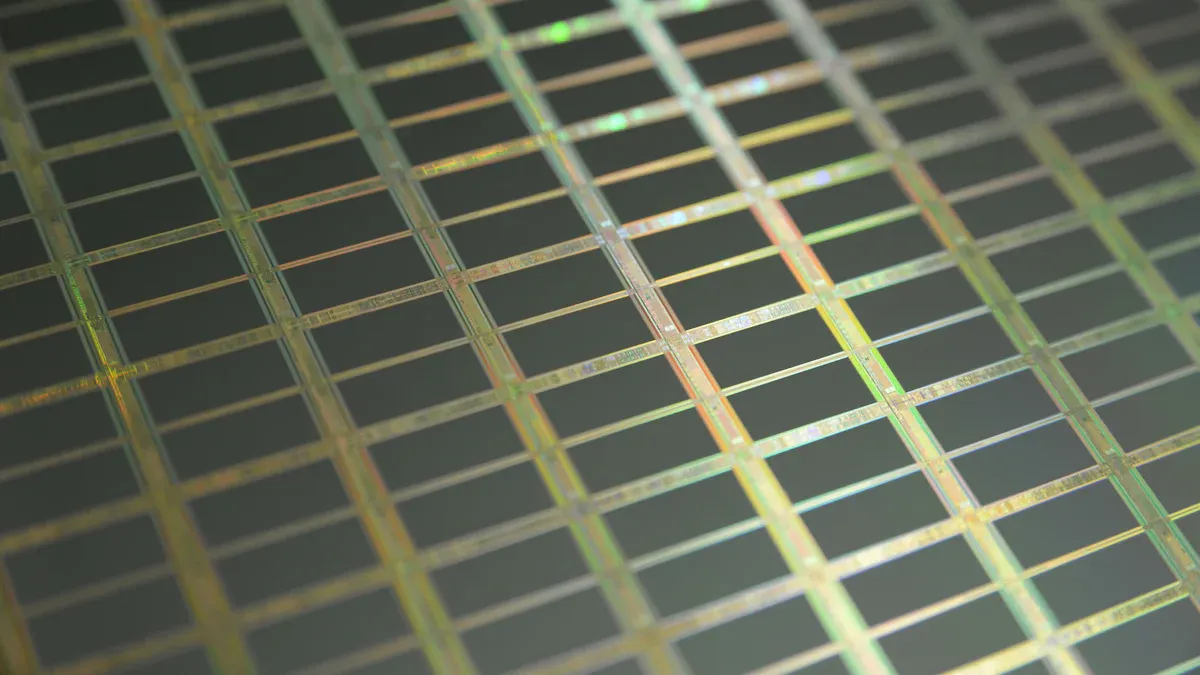

The semiconductor industry demands tools that enhance precision and durability. SiC wafer holders meet these needs by supporting high-performance applications. You benefit from their ability to handle larger wafer sizes and withstand intense processing demands. Their integration with the SiC process tube and advancements in the SiC coating process make them essential for modern manufacturing.

Key Takeaways

- SiC wafer holders help make chips with better quality and last longer.

- Using good SiC wafer holders cuts delays and makes more chips, saving money and time.

- Pick SiC wafer holders by checking material strength, heat resistance, and if they fit your tools.

Importance of SiC Wafer Holders

Key Functions and Benefits

SiC wafer holders play a vital role in semiconductor manufacturing. They provide a stable platform for wafers during critical processes like etching, deposition, and thermal treatment. This stability ensures that your wafers remain undamaged and aligned, which is essential for producing high-quality chips.

One of their standout benefits is durability. SiC wafer holders resist wear and tear, even under extreme conditions. Their ability to withstand high temperatures and chemical exposure makes them ideal for demanding applications. You can rely on them to maintain their structural integrity, reducing the need for frequent replacements.

Another key advantage is precision. SiC wafer holders are designed to fit seamlessly with modern equipment, ensuring accurate positioning and alignment. This precision minimizes errors and boosts efficiency, helping you achieve consistent results in your manufacturing processes.

Tip: Investing in high-quality SiC wafer holders can save you time and money by reducing downtime and improving production yields.

Impact of Technological Advancements on SiC Wafer Holders

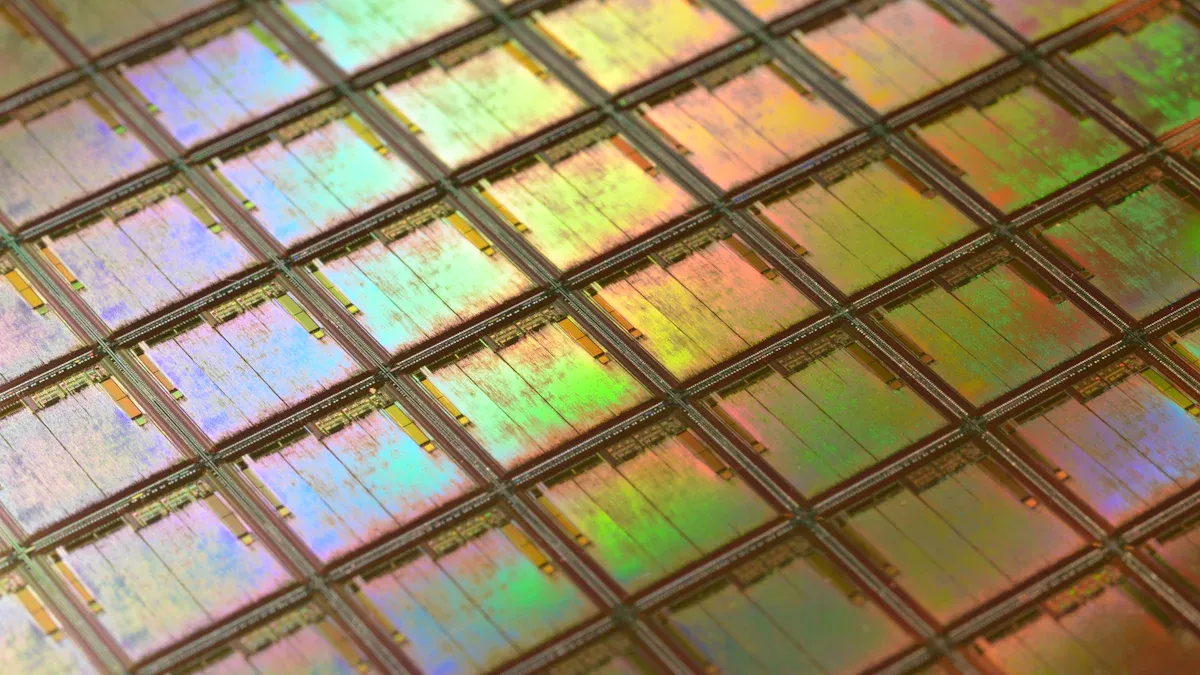

Advancements in semiconductor technology have transformed SiC wafer holders into indispensable tools. Larger wafer sizes, such as 200mm and 300mm, require holders that can support increased weight and surface area without compromising stability. Modern SiC wafer holders meet these demands with enhanced designs and materials.

Higher processing speeds and temperatures also demand superior thermal resistance. SiC wafer holders excel in this area, maintaining their performance even under extreme heat. This makes them a perfect match for cutting-edge manufacturing techniques like rapid thermal processing.

Compatibility with automated systems is another area where technology has pushed SiC wafer holders forward. You benefit from holders that integrate seamlessly with robotic arms and advanced machinery, ensuring smooth operations and reducing human error.

Note: As semiconductor technology evolves, choosing SiC wafer holders that align with future trends will keep your processes efficient and competitive.

Criteria for Evaluating SiC Wafer Holders

Material Quality and Durability

When choosing a SiC Wafer Holder, material quality should be your top priority. High-quality materials ensure the holder can withstand the rigors of semiconductor manufacturing. Silicon carbide (SiC) is known for its exceptional hardness and resistance to wear. This makes it an ideal choice for holders that need to endure repeated use without degrading.

Durability is equally important. A durable holder reduces the risk of breakage during handling or processing. This saves you money on replacements and minimizes downtime in your operations. Always look for holders made from premium SiC to ensure long-lasting performance.

Tip: Check for certifications or industry standards that guarantee the material’s quality.

Thermal and Chemical Resistance

Semiconductor processes often involve extreme temperatures and exposure to harsh chemicals. A good SiC Wafer Holder must resist these conditions without losing its structural integrity. SiC’s natural thermal stability allows it to perform well in high-temperature environments.

Chemical resistance is another critical factor. Holders exposed to corrosive substances must maintain their performance. This ensures your wafers remain protected throughout the manufacturing process.

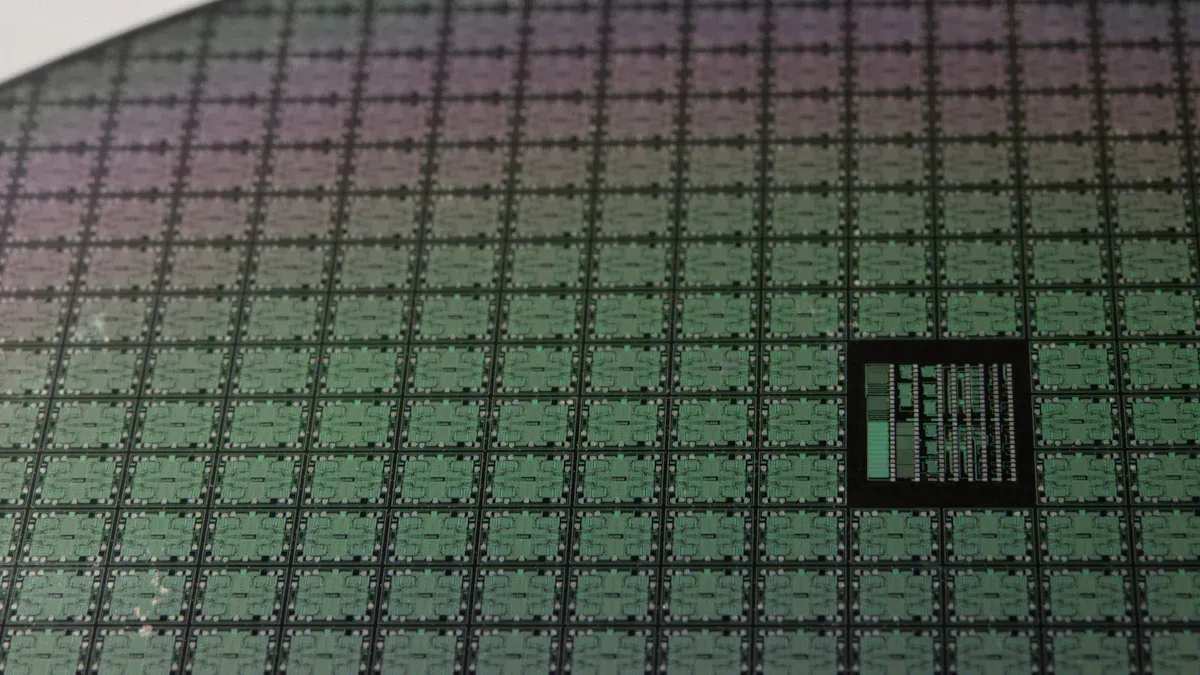

Precision and Compatibility with Equipment

Precision is key in semiconductor manufacturing. A SiC Wafer Holder must align perfectly with your equipment to prevent errors. Poor alignment can lead to defects in your wafers, which impacts the quality of your final products.

Compatibility with modern machinery is also essential. Many manufacturing systems now use automation. Your holder should integrate seamlessly with robotic arms and other automated tools. This improves efficiency and reduces the chance of human error.

Note: Always verify that the holder matches the specifications of your equipment before purchasing.

Comparison of Top SiC Wafer Holder Products

Product 1: STMicroelectronics SiC Wafer Holder – Features, Pros, Cons, and Use Cases

STMicroelectronics offers a SiC Wafer Holder designed for precision and durability. Its lightweight structure ensures easy handling during manufacturing processes. The holder’s high thermal resistance makes it suitable for applications involving extreme temperatures.

Pros:

- Excellent thermal stability.

- Lightweight design reduces strain on automated systems.

- Compatible with a wide range of semiconductor equipment.

Cons:

- Higher cost compared to other options.

- Limited availability in some regions.

Use Cases:

This holder works well in high-temperature processes like rapid thermal annealing and chemical vapor deposition.

Product 2: Infineon Technologies SiC Wafer Holder – Features, Pros, Cons, and Use Cases

Infineon Technologies provides a robust SiC Wafer Holder known for its chemical resistance. Its durable construction ensures long-term use without degradation. The holder integrates seamlessly with automated systems, improving operational efficiency.

Pros:

- Superior chemical resistance.

- Long-lasting performance under harsh conditions.

- Designed for compatibility with modern automation tools.

Cons:

- Heavier than other options, which may affect some systems.

- Slightly less precise in alignment compared to competitors.

Use Cases:

Ideal for processes involving corrosive chemicals, such as etching and cleaning.

Product 3: Wolfspeed SiC Wafer Holder – Features, Pros, Cons, and Use Cases

Wolfspeed’s SiC Wafer Holder stands out for its precision and adaptability. Its design ensures accurate wafer alignment, reducing the risk of defects. The holder’s moderate weight makes it suitable for both manual and automated handling.

Pros:

- High precision for wafer alignment.

- Adaptable to various equipment types.

- Moderate weight for versatile use.

Cons:

- Limited thermal resistance compared to other products.

- May require more frequent replacements in high-temperature environments.

Use Cases:

Best suited for general semiconductor manufacturing processes requiring high precision.

Summary Table Comparing All Products

| Feature/Aspect | STMicroelectronics | Infineon Technologies | Wolfspeed |

|---|---|---|---|

| Thermal Resistance | Excellent | Good | Moderate |

| Chemical Resistance | Moderate | Excellent | Good |

| Precision | High | Moderate | High |

| Weight | Lightweight | Heavy | Moderate |

| Best Use Case | High-temperature processes | Corrosive chemical processes | General manufacturing |

Recommendations

Best Overall Product for General Use

If you need a versatile solution, the Wolfspeed SiC Wafer Holder is your best choice. Its high precision ensures accurate wafer alignment, which reduces defects and improves production quality. The moderate weight makes it easy to handle, whether you use manual or automated systems. This adaptability makes it suitable for a wide range of semiconductor manufacturing processes.

While its thermal resistance is not as high as other options, it performs well in standard manufacturing environments. You can rely on it for consistent results without frequent replacements. For general use, this product strikes the perfect balance between performance and practicality.

Best Product for High-Temperature Applications

For high-temperature processes, the STMicroelectronics SiC Wafer Holder stands out. Its excellent thermal stability allows it to withstand extreme heat without compromising performance. This makes it ideal for applications like rapid thermal annealing and chemical vapor deposition.

The lightweight design also reduces strain on automated systems, ensuring smooth operations. Although it comes at a higher cost, the durability and reliability it offers make it a worthwhile investment for demanding environments.

Budget-Friendly Option

If you are looking for an affordable yet reliable option, consider the Infineon Technologies SiC Wafer Holder. Its superior chemical resistance ensures long-term performance, even in harsh conditions. While it is heavier and slightly less precise than other products, it still delivers solid results for processes involving corrosive chemicals.

This product is a great choice if you need a cost-effective solution without sacrificing essential features. It provides durability and compatibility with modern equipment, making it a practical option for budget-conscious manufacturers.

SiC Wafer Holders play a crucial role in improving semiconductor manufacturing. They enhance precision, durability, and efficiency. Among the top products, STMicroelectronics excels in high-temperature applications, Wolfspeed offers versatility, and Infineon Technologies provides cost-effective chemical resistance. Choose a holder based on your specific needs, such as temperature tolerance, precision, or budget.

FAQ

What makes SiC wafer holders better than traditional holders?

SiC wafer holders offer superior thermal and chemical resistance. They also provide better durability and precision, making them ideal for high-performance semiconductor manufacturing processes.

How do I choose the right SiC wafer holder for my needs?

Focus on your manufacturing requirements. Consider factors like temperature tolerance, chemical exposure, and compatibility with your equipment. Always prioritize material quality and durability.

Tip: Consult your equipment specifications to ensure compatibility before purchasing.

Are SiC wafer holders compatible with automated systems?

Yes, most modern SiC wafer holders integrate seamlessly with automated systems. This ensures smooth operations, reduces human error, and improves overall manufacturing efficiency.